Table of Contents

1. Introduction: The End of High-Maintenance Exteriors

You love the warmth, texture, and sophisticated profile of natural timber. It defines architectural beauty. But let’s be honest about the reality of owning it. You do not love the weekend hours lost to sanding, the toxic fumes of staining, the anxiety of watching boards warp in the summer heat, or the sinking feeling of spotting rot near the foundation.

For decades, homeowners, architects, and investors faced a binary choice: suffer the relentless maintenance of wood or settle for the sterile, industrial look of vinyl or concrete.

That era is over.

Composite Cladding has emerged as the definitive game-changer in modern construction. It is the intersection where materials science meets aesthetic design. It offers the authentic, tactile experience of timber without the biological flaws.

This isn’t just about changing the color of your house; it is about upgrading the structural integrity and financial value of your property. In this comprehensive guide, we will strip away the marketing noise and look at the engineering, the economics, and the installation realities of composite cladding. We will explore why smart investors are moving away from timber and fiber cement, and exactly how this material delivers a Return on Investment (ROI) that outperforms traditional siding options.

Welcome to the future of exterior facade design.

2. What is Composite Cladding? Understanding WPC Tech

To understand why composite cladding performs so well, we must look at its DNA. It is not simply “plastic siding.” It is a highly engineered hybrid material, often referred to within the industry as WPC (Wood Plastic Composite).

Definition: Wood Plastic Composite (WPC)

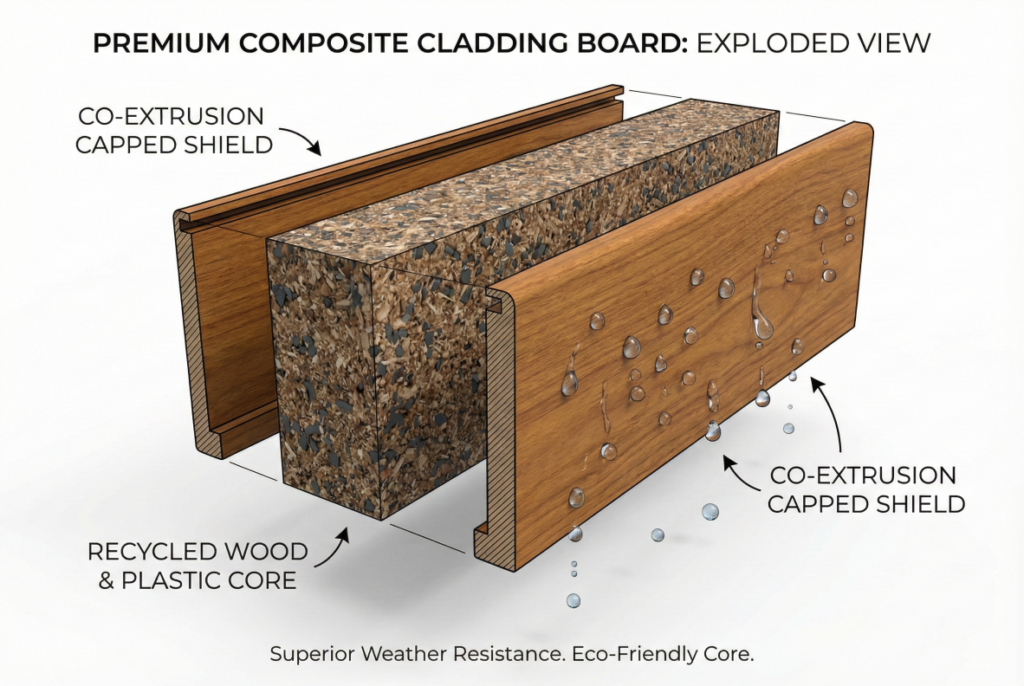

WPC is a composite material made of wood fiber/wood flour and thermoplastic(s) such as PE, PP, PVC, or PLA. In high-end cladding, this is typically a blend of approximately 60% recycled hardwood fibers and 40% recycled High-Density Polyethylene (HDPE), combined with bonding agents and UV stabilizers.

The Composition: Wood Fibers Meets Polymer Science

The genius of composite cladding lies in the synergy of its components. The wood fibers provide the tensile strength, the rigidity, and—crucially—the natural aesthetic. The plastic component (HDPE) provides the armor. It binds the wood fibers, sealing them off from moisture, insects, and decay. This combination creates a board that is as workable as wood but as durable as synthetic decking.

However, not all composites are created equal. The industry standard has shifted from “First Generation” (uncapped) composites to “Second Generation” (capped) technology.

Co-Extrusion Technology: The “Capped” Shield

The most durable options on the market today utilize Co-extrusion technology. Imagine the core of the board (the composite blend) is the muscle. Co-extrusion wraps that muscle in a 360-degree, impermeable outer shell—the “Cap.”

This cap is a high-performance polymer shield that is fused to the core during the manufacturing process under extreme heat. This shield is responsible for:

-

Stain Resistance: Oils, wines, and pollutants cannot penetrate the surface.

-

Scratch Resistance: It protects against physical abrasion from tree branches or hail.

-

Color Fastness: It locks in the pigment, preventing the dreaded “grey-out” associated with timber.

[Image Suggestion: Exploded view diagram showing the core composite material and the outer ‘Cap’ shield layer]

3. 7 Reasons to Choose WPC Siding Over Wood

Why is the market shifting so aggressively toward composite? It comes down to seven distinct performance vectors where composite cladding simply outclasses the competition.

Unmatched Longevity (25-30 Year Lifespan)

Natural timber begins to degrade the moment it is installed. It is organic; it wants to decompose. Composite cladding is engineered to resist nature. A high-quality composite board typically carries a warranty of 25 to 30 years, but its practical lifespan can extend far beyond that.

Because the material is non-porous, it does not crack, splinter, or warp due to moisture absorption. When you install composite, you are effectively “future-proofing” the building envelope for the next three decades. This durability makes it a favorite for commercial buildings where replacement costs are prohibitive.

Zero Maintenance: The “No Sanding” Guarantee

This is the single biggest selling point for homeowners. With timber siding, you are signing up for a maintenance schedule that includes stripping, sanding, and oiling every 2-3 years to keep the warranty valid. If you miss a cycle, the wood degrades.

The “No Sanding/Painting” Rule: Composite cladding requires zero structural maintenance. It does not need painting, sealing, or oiling—ever.

-

Time Saved: Over a 10-year period, the average homeowner saves approximately 200+ hours of labor.

-

Money Saved: You eliminate the cost of stains, brushes, scaffolding rentals, and professional painters.

UV Stability & Fade Resistance

One of the primary complaints about wood (especially Cedar or Redwood) is how quickly the rich colors turn into a dull, silvery grey under the sun. This happens because UV rays break down the lignin in the wood cells.

High-end WPC siding incorporates UV stabilizers directly into the “Cap” layer. While all materials experience a slight weathering in the first few weeks as they acclimatize, composite holds roughly 95% of its original hue for decades. A Charcoal Black board installed today will still be Charcoal Black in 2040.

Termite, Rot, and Moisture Proofing

If you live in a region prone to high humidity or termite activity, timber is a liability. Termites do not eat plastic. Fungi cannot breed without moisture penetration. Because the wood fibers in composite are encapsulated in HDPE, the material is biologically inert to pests and mold. You will never have to pay for an exterminator to treat your exterior walls or worry about structural rot compromising the facade.

Eco-Friendly Materials & Sustainability

It seems counter-intuitive to call a product containing plastic “eco-friendly,” but the math supports it.

-

Recycled Content: Top-tier manufacturers use up to 95% recycled materials. Every square meter of cladding diverts thousands of plastic bottles from landfills and utilizes tons of wood scrap (sawdust) that would otherwise be incinerated.

-

No Toxic Chemicals: Unlike pressure-treated lumber, which is often infused with copper azole or other biocides to prevent rot, composite is toxin-free. It protects the soil around your home from chemical leaching.

Class B Fire Ratings & Safety

In the wake of changing building codes and increased wildfire risks, fire-rated exterior cladding is no longer a luxury—it is a necessity. While standard timber is fuel, modern composite cladding is formulated with fire retardants. Many high-quality boards achieve a Class B fire rating, meaning they have low flame spread and do not contribute significantly to flashover. This is a critical factor for insurance premiums and safety in bushfire-prone zones.

Thermal Insulation Properties

While cladding is primarily a rain screen, composite offers better thermal properties than fiber cement or metal. It acts as an additional thermal break, helping to stabilize the internal temperature of the building. When combined with proper insulation batts and a breathable membrane, composite cladding contributes to a tighter, more energy-efficient building envelope, lowering HVAC costs over time.

4. Comparison: Composite Cladding vs. Timber vs. Fiber Cement

To make an informed decision, we must look at the data. How does composite stack up against the old guard (Timber) and the industrial contender (Fiber Cement)?

[Internal Link: View our detailed technical comparison charts]

The Material Comparison Matrix

| Feature | Composite Cladding | Traditional Timber (Cedar/Larch) | Fiber Cement |

| Initial Material Cost | Moderate to High | Moderate (Variable by species) | Low to Moderate |

| Installation Cost | Moderate (Clip system) | Moderate | High (Heavy, requires specialized tools) |

| Maintenance Freq. | None (Wash only) | High (Paint/Stain every 2-3 yrs) | Moderate (Repaint every 10-12 yrs) |

| 10-Year Total Cost | Lowest | Highest (Labor + Materials) | Moderate |

| Rot/Insect Resistance | Impervious | Low (Unless chemically treated) | High |

| Weight | Moderate | Light | Heavy (Difficult to handle) |

| Aesthetic Consistency | Perfect consistency | High variance (Knots, warping) | Artificial/Flat appearance |

| Eco-Impact | High (Recycled) | Variable (Deforestation concerns) | Moderate (High energy manufacturing) |

Analysis: The “Total Cost of Ownership” Reality

When you look at the table above, one thing becomes clear: Timber is a subscription service; Composite is a one-time purchase.

While fiber cement is a strong competitor regarding durability, it falls short on aesthetics and ease of handling. It is heavy, brittle, and difficult to cut, often driving up installation labor costs due to the need for specialized diamond blades and dust management. Furthermore, fiber cement still requires repainting eventually.

Timber may have a slightly lower upfront cost (depending on the species), but the “10-Year Total Cost” column is where the battle is lost. When you factor in the cost of stains, sealants, and your own labor value over a decade, timber becomes the most expensive option by a significant margin.

Composite cladding wins the “Long-term Value” battle because it freezes your costs at the moment of purchase. You pay for the quality once, and the asset performs for decades without demanding another cent.

5. Modern Facade Design: Colors, Textures & Trends

Gone are the days when composite materials looked like shiny, fake plastic. Through advancements in 3D embossing, modern facade design can be virtually indistinguishable from organic wood.

3D Wood Grain vs. Brushed Flat Textures

-

3D Wood Grain: These boards feature deeply embossed patterns that mimic the cathedrals, knots, and ticking of natural oak or cedar. These catch the light differently throughout the day, providing depth and character.

-

Brushed/Sanded Flat: For modern, minimalist architecture, a brushed finish offers a clean, matte look that resembles sanded timber before staining. This is highly popular in “Japandi” and mid-century modern renovations.

[Image Suggestion: Side-by-side comparison of 3D wood grain vs. Brushed Flat texture]

Trending Colors: Teak, Charcoal & Grey

The current market is moving away from basic browns into sophisticated architectural palettes:

-

Teak & Ipe: Rich, warm tones that mimic tropical hardwoods. Perfect for adding warmth to concrete or brick structures.

-

Charcoal & Midnight Black: The “Shou Sugi Ban” (burnt timber) look is trending heavily. Composite allows you to achieve this dramatic, charred aesthetic without the mess of carbon dust.

-

Silver Grey: Mimics the look of naturally weathered driftwood, ideal for coastal properties.

Layout Styles: Horizontal, Vertical, & Diagonal

The versatility of composite allows for creative cladding installation guides and layouts:

-

Horizontal (Ship-lap): The traditional, timeless look. Expands the visual width of the house.

-

Vertical: A contemporary choice that makes buildings appear taller and sleeker. Very popular in “Barndominium” designs.

-

Diagonal/Herringbone: For feature walls or entryways, diagonal installation creates a stunning architectural focal point.

6. Installation Guide: DIY Tips & Best Practices

Can you install composite cladding yourself? The short answer is yes—if you have basic carpentry skills and the right tools. Unlike fiber cement, which requires diamond blades and is prone to cracking, composite cuts and drills much like wood.

The Hidden Clip System Explained

Most modern composite cladding uses a hidden clip system. This is a major aesthetic advantage over face-screwing timber.

-

Starter Clips: Installed at the bottom of the wall to hold the first board.

-

Interlocking Boards: The boards feature a tongue-and-groove profile. You screw the top flange into the joist, and the next board slides over it, hiding the screw head. This results in a flawless, fastener-free finish.

Critical Joist Spacing & Airflow

This is where DIYers often make mistakes.

-

Joist Spacing: You must install battens (sub-frame) at specific intervals, typically 300mm to 400mm centers. If you space them too wide, the boards may flex or bow.

-

Ventilation: Composite cladding is a “rain screen.” You must leave an airflow gap behind the boards (created by the battens) to allow condensation to evaporate. Never install cladding directly against a flat wall without battens.

Managing Thermal Expansion Gaps

Composite materials expand and contract with temperature changes more than wood does. This is the most critical technical detail in installation.

-

The Gap Rule: You must leave expansion gaps (usually 3-5mm) where the boards meet corners, windows, or other boards (butt joints).

-

The Risk: If you butt the boards tightly together in winter, they will buckle and warp when the summer heat expands them. Always follow the manufacturer’s temperature gap chart.

7. Cost Analysis & Return on Investment (ROI)

Let’s talk numbers. Why should you invest in composite vs timber cladding cost?

Price Per Square Meter Breakdown

As of 2024, high-quality capped composite cladding typically ranges from $80 to $120 per square meter (materials only).

-

Vinyl: $40 – $60 / m² (Lower ROI, lower durability)

-

Cedar: $90 – $140 / m² (High maintenance, variable pricing)

-

Composite: $80 – $120 / m² (Balanced sweet spot)

While the initial sticker price is higher than cheap vinyl or pine, it is comparable to premium Cedar. However, the true value lies in the lifecycle cost.

Boosting Curb Appeal & Resale Value

Real estate investors know that the exterior facade is the “first impression.” A home clad in rotting wood screams “money pit” to a potential buyer. A home clad in pristine, modern composite screams “low maintenance luxury.”

Upgrading to composite cladding is widely cited to provide a 70% to 80% ROI upon resale, making it one of the most profitable exterior renovations you can perform. It signals to buyers that the home is well-cared for and mechanically sound.

8. Composite Cladding FAQs

Here are the most common questions we receive from homeowners and contractors.

Can you paint composite cladding?

You generally can, but you shouldn’t have to. The point of composite is that it comes pre-colored and sealed. Painting it introduces a maintenance cycle you paid to avoid. If you want to change the color later, it is possible with specialized plastic primers, but it is not recommended.

Does composite siding get hot in the sun?

Like any material, dark colors absorb heat. However, modern composite transfers heat differently than metal. While it will get warm to the touch in direct sunlight, the “capped” technology helps dissipate heat better than older plastic generations. If heat is a major concern, opt for lighter shades like Teak or Grey.

What is the best way to clean cladding?

Put away the pressure washer (or use it on a very low setting). All you typically need is warm water, a soft-bristle brush, and mild dish soap. Wash it down once or twice a year to remove pollen and dust. That’s it.

Conclusion: Make the Smart Investment

The decision to upgrade your home’s exterior is significant. It impacts your home’s protection, its aesthetic beauty, and its financial value.

Traditional timber had its time, but the future belongs to smarter materials. Composite cladding offers the perfect marriage of nature-inspired beauty and industrial-grade durability. It solves the pain points of rot, maintenance, and fire safety, all while delivering a modern, high-end look that lasts for decades.

If you are tired of the maintenance trap and want to elevate your property value, composite is the smartest investment you can make this year.

Ready to see the difference?

Don’t just take our word for it. Pictures can’t convey the texture and weight of our premium boards.