Table of Contents

Introduction: The $50,000 Mistake You Can Avoid

Last year, a property developer in Florida invested $50,000 in WPC decking for a luxury resort project, only to discover severe warping and color fading within 18 months. The manufacturer had disappeared, the warranty was worthless, and the entire installation required replacement. This wasn’t an isolated incident—industry data shows that approximately 35% of WPC projects experience quality issues within the first five years, and poor manufacturer selection is the leading cause.

Choosing the right WPC manufacturer isn’t simply about comparing price quotes. It’s about protecting a significant investment and ensuring your wood plastic composite products deliver the 20-25 year lifespan they promise. Whether you’re a contractor, architect, property developer, or homeowner planning a major project, the manufacturer you select will determine whether your WPC installation becomes a showcase or a cautionary tale.

This comprehensive guide provides a proven, step-by-step framework for evaluating WPC manufacturers across nine critical dimensions. You’ll discover specific questions to ask, red flags to watch for, and technical benchmarks that separate exceptional suppliers from problematic ones.

Manufacturing Capabilities: The Foundation of Quality

Your WPC manufacturer’s production technology directly impacts product consistency and durability. Understanding their capabilities helps you separate sophisticated operations from basic workshops.

Extrusion Technology Makes the Difference

The gap between single-screw and co-extrusion technology is enormous. Basic single-screw extruders mix wood flour and plastic but create a homogeneous product vulnerable to moisture and UV damage. Advanced co-extrusion systems, by contrast, wrap a protective polymer shell around the composite core, delivering superior weather resistance and longevity.

Ask every potential WPC supplier: “Do you use co-extrusion technology, and what percentage of your product line features this process?” Manufacturers with twin-screw co-extrusion equipment typically invest $500,000-$2 million per production line, indicating serious commitment to quality.

Production Capacity Signals Stability

Annual production capacity reveals market position and reliability. Established composite decking manufacturers typically produce 5,000-50,000 tons annually. Lower volumes might indicate newer operations with unproven track records, while extremely high volumes could suggest mass production that compromises customization.

Request specific numbers: “What is your annual production capacity, and what percentage is currently allocated?” This helps you assess whether they can handle your project timeline without overextending resources.

Quality Control Infrastructure

In-house testing facilities separate serious manufacturers from resellers. Look for laboratories equipped to perform:

- Density testing (target range: 0.9-1.2 g/cm³)

- Water absorption analysis (ASTM D570 standard)

- Flexural strength measurements

- Color fastness evaluation

- Surface hardness testing

Manufacturers without testing equipment rely on external labs, creating delays and potential accountability gaps.

Product Quality Verification: What’s Actually in Your WPC?

The composition of wood plastic composite material determines performance, yet many buyers never ask what’s inside the product they’re purchasing.

Raw Material Transparency Matters

Premium WPC manufacturers clearly disclose their formulations. Standard compositions include:

- Wood flour content: 40-70% (higher percentages increase natural appearance but may reduce water resistance)

- Plastic content: 30-60% (virgin HDPE performs better than recycled alternatives)

- Coupling agents: 1-3% (critical for bonding wood and plastic molecules)

- UV stabilizers and additives: 1-5%

Ask bluntly: “What is your exact wood-to-plastic ratio, and do you use virgin or recycled plastic?” Evasive answers suggest quality concerns. Manufacturers using 100% recycled plastic may offer lower prices but typically deliver inconsistent color and reduced structural integrity.

Surface Finish Quality Standards

WPC products come in multiple surface treatments—sanding, brushing, embossing, or wood grain patterns. Examine sample boards closely under bright lighting. Quality indicators include:

- Consistent grain patterns without irregular patches

- Uniform color distribution (no blotching or streaking)

- Smooth finish without splinters or rough edges

- Consistent board dimensions (length, width, thickness variations under 2mm)

Request samples from different production batches to verify consistency over time.

Performance Testing Documentation

Reputable WPC manufacturers provide detailed technical data sheets showing:

- Water absorption rates (should be <1% for quality products)

- Slip resistance ratings (typically ASTM C1028 or EN 13893)

- Load-bearing capacity (minimum 1,000 kg/m² for residential decking)

- Flexural modulus values

- Temperature expansion rates

Without this documentation, you’re buying on faith rather than facts.

Certification & Compliance Standards: Your Quality Insurance Policy

Certifications aren’t marketing fluff—they’re independently verified proof of quality and safety compliance.

Essential Certifications by Market

Different regions require different certifications for WPC products:

North America:

- ICC-ES certification (International Code Council Evaluation Service)

- ASTM D7032 standard for WPC deck boards

- ADA compliance for accessibility requirements

- Fire rating certifications (Class A, B, or C depending on application)

Europe:

- CE marking (mandatory for construction products)

- EN 15534 standards for WPC composites

- FSC certification for sustainable wood sourcing

Global Standards:

- ISO 9001 for quality management systems

- ISO 14001 for environmental management

Ask your WPC supplier: “Which certifications do you currently hold, and can you provide copies of certificates with valid dates?” Check certification validity through issuing organizations’ websites—expired or fake certificates are surprisingly common.

Environmental Credentials

Sustainability-focused projects require specific environmental certifications:

- LEED credit eligibility documentation

- GreenGuard certification for low chemical emissions

- FSC or PEFC chain-of-custody certification

- Cradle-to-Cradle ratings

These certifications cost manufacturers $10,000-$50,000 to obtain and maintain, representing significant commitment to environmental responsibility.

Customization & Technical Support: Beyond Standard Products

Your project likely has specific requirements. The right WPC manufacturer should function as a technical partner, not just a product supplier.

Design Flexibility Assessment

Quality composite decking manufacturers offer:

- Custom profile extrusion (unique board shapes and dimensions)

- Color matching services (matching existing installations or architectural palettes)

- Custom lengths (reducing waste and installation time)

- Special finishes (anti-slip coatings, enhanced grain patterns)

Standard manufacturers stock 8-12 color options. Premium suppliers offer 20+ standard colors plus custom color development. Ask: “What is your minimum order quantity for custom colors, and what is the development timeline?”

Technical Documentation Quality

Professional WPC suppliers provide comprehensive technical support:

- Detailed installation manuals with step-by-step instructions

- CAD drawings for custom profiles

- Load calculation assistance for structural applications

- Thermal expansion guidelines for your climate zone

- Maintenance protocols extending product lifespan

Request samples of their documentation before committing. Poor documentation indicates inadequate technical expertise.

Sample Provision Policies

Legitimate manufacturers readily provide samples, typically:

- Free sample pieces (6-12 inches) for color verification

- Full-length sample boards (at cost) for installation testing

- Multiple surface finish options for comparison

Be suspicious of suppliers charging excessive fees for basic samples or refusing to provide them entirely.

Business Reliability Indicators: Who Will Still Be There in Five Years?

Product quality means nothing if your manufacturer vanishes when warranty claims arise.

Longevity and Track Record

Prioritize WPC manufacturers operating for 5+ years. The composite decking industry sees high failure rates among new entrants—companies lacking the capital, expertise, or commitment to survive market fluctuations.

Request: “Provide three completed projects from 5+ years ago that we can inspect or contact for references.” Current projects only demonstrate sales success, not long-term product performance.

Client Portfolio Diversity

Healthy manufacturers serve diverse market segments:

- Residential contractors

- Commercial developers

- Government infrastructure projects

- Marine and waterfront applications

Over-reliance on single market segments creates vulnerability. Review case studies and ask for client contact information.

Financial Stability Markers

While you likely can’t access financial statements, indirect indicators include:

- Own their production facility (vs. leasing)

- Continuous equipment upgrades

- Active R&D department

- Participation in industry trade shows

- Professional website and marketing materials

Communication Excellence

Evaluate responsiveness and communication quality from first contact:

- Response time to inquiries (within 24-48 hours for quality suppliers)

- Technical knowledge of sales staff

- Availability of English-speaking representatives for international buyers

- Willingness to arrange factory visits

- Clarity of quotes and specifications

Poor communication during sales predicts worse communication during production and after-sales support.

Warranty & After-Sales Service: What Happens When Problems Arise

Warranty terms reveal manufacturer confidence in their products and commitment to customer satisfaction.

Warranty Coverage Analysis

Standard WPC warranties range from 10-25 years, but coverage details matter more than duration:

Residential vs. Commercial Terms:

- Residential: Typically 20-25 years limited warranty

- Commercial: Usually 10-15 years (higher traffic demands)

What’s Actually Covered:

- Material defects (standard coverage)

- Color fading (often limited to specific percentage, e.g., no more than 10% color change)

- Staining resistance (may exclude certain substances)

- Structural integrity (warping, splitting, cracking)

Critical Exclusions:

- Improper installation (most common claim denial)

- Normal wear and tear definition

- Scratches and surface damage

- Acts of nature (hurricanes, floods)

Ask specifically: “What percentage of color fade is acceptable under your warranty, and what documentation do you require for claims?”

Claim Process Transparency

Request the warranty claim procedure in writing. Red flags include:

- Requiring international shipping of failed products at customer expense

- Mandatory third-party inspection fees

- Vague timelines for claim resolution

- No clear replacement product provision

Quality WPC manufacturers maintain replacement inventory for discontinued products and resolve legitimate claims within 30-60 days.

Sustainability & Environmental Practices: Manufacturing Responsibility

Environmental credentials increasingly influence purchasing decisions and project eligibility.

Recycled Content Verification

Many WPC products claim environmental benefits through recycled content. Verify:

- Percentage of post-consumer recycled plastic (30-95% typical)

- Source of wood flour (sawmill waste, agricultural residuals, or virgin timber)

- Third-party verification of recycled content claims

Higher recycled content isn’t automatically better—balance environmental benefits against performance requirements.

Manufacturing Environmental Impact

Progressive composite manufacturers implement:

- Closed-loop water recycling systems

- Energy-efficient extrusion processes

- Solar power integration

- Waste material recycling programs (scrap becomes new product)

- VOC (Volatile Organic Compound) reduction initiatives

Request information about their carbon footprint and environmental initiatives. Genuine commitment includes measurable targets and progress reporting.

End-of-Life Recyclability

Unlike pressure-treated wood, quality WPC products can be recycled at end of life. Ask: “Are your products recyclable, and do you offer take-back programs?” Forward-thinking manufacturers increasingly accept used products for recycling into new materials.

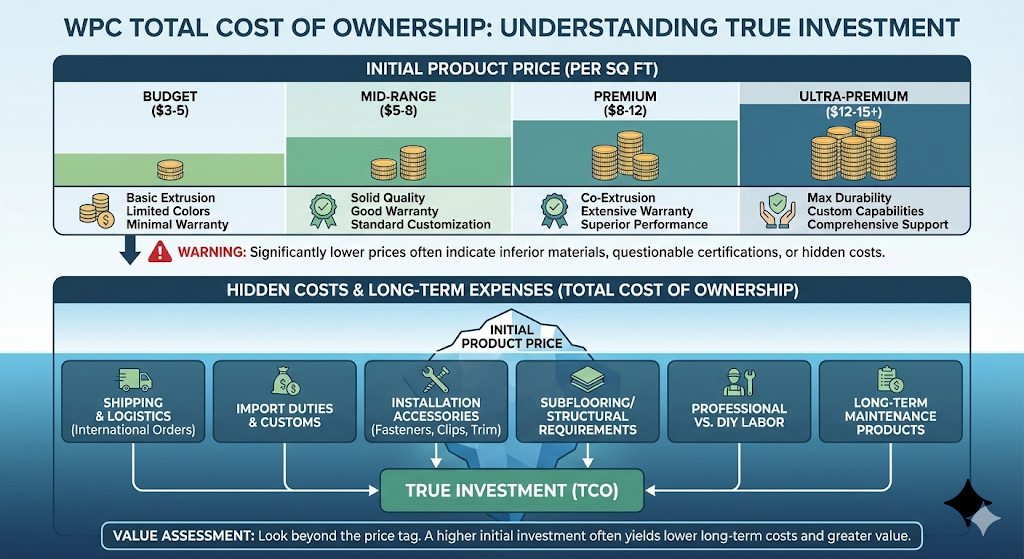

Cost Analysis & Value Assessment: Understanding True Investment

Price comparison requires understanding total cost of ownership, not just initial purchase price.

Market Price Ranges

Typical WPC pricing (per square foot/meter varies by region):

- Budget tier: $3-5/sq ft (basic extrusion, limited colors, minimal warranty)

- Mid-range: $5-8/sq ft (solid quality, good warranty, standard customization)

- Premium: $8-12/sq ft (co-extrusion, extensive warranty, superior performance)

- Ultra-premium: $12-15+/sq ft (maximum durability, custom capabilities, comprehensive support)

Prices significantly lower than regional averages deserve scrutiny—they often indicate inferior materials, questionable certifications, or hidden costs.

Hidden Cost Identification

Factor these additional expenses into total cost:

- Shipping and logistics (international orders may double costs)

- Import duties and customs clearance

- Installation accessories (fasteners, starter clips, edge trim)

- Subflooring or structural requirements

- Professional installation vs. DIY labor

- Long-term maintenance products

Value Comparison Methodology

Create a weighted scoring system evaluating:

- Initial price per square foot (20% weight)

- Warranty coverage and duration (20%)

- Expected lifespan and durability (25%)

- Maintenance requirements (15%)

- Aesthetic appeal and customization (10%)

- Manufacturer reputation and support (10%)

This framework prevents over-focusing on purchase price while neglecting long-term value.

Red Flags & Deal Breakers: Walk Away from These Warning Signs

Certain behaviors indicate unreliable WPC manufacturers. Protect your investment by recognizing these red flags:

Immediate Disqualifiers:

- Refusal to provide samples or factory tours – Legitimate manufacturers welcome inspection

- No verifiable certifications – Claiming certifications without providing documentation

- Unrealistic warranties – 30-50 year warranties without substance or company history to support them

- Pricing 40%+ below market average – Indicates substandard materials or outright fraud

- Poor communication or disappeared contacts – Unresponsive during sales means disaster during problems

- No quality control documentation – Cannot provide testing procedures or results

- Vague product specifications – Unwilling to disclose formulations or technical data

- Pressure tactics – “Limited time offers” or aggressive sales approaches

- No established business presence – PO box addresses, temporary offices, no manufacturing facility verification

- Inconsistent information – Specifications change between conversations or documents

Concerning but Not Disqualifying:

- Recently established companies (under 3 years) – acceptable with strong backing and transparent operations

- Limited customization options – fine for standard projects

- Higher prices – often justified by superior quality

- Minimum order quantities – standard practice for custom work

Decision-Making Framework: Your Step-by-Step Evaluation Process

Transform overwhelming options into confident decisions using this systematic approach:

Phase 1: Initial Research (Week 1)

- Identify 8-10 potential WPC manufacturers through industry directories, trade shows, and referrals

- Request basic information packages from each

- Eliminate obvious non-starters based on red flags

- Shortlist 4-5 manufacturers for detailed evaluation

Phase 2: Deep Evaluation (Weeks 2-3)

- Request and review samples from all shortlisted suppliers

- Conduct detailed phone/video consultations asking:

- “Describe your extrusion technology and quality control processes”

- “Provide client references from projects completed 5+ years ago”

- “Explain your warranty claim process with typical resolution timeline”

- “What certifications do you hold, and can you provide current documentation?”

- “Describe your customization capabilities and minimum order requirements”

- Verify certifications through issuing organizations

- Contact at least two references per manufacturer

- Request detailed quotes including all costs and specifications

Phase 3: Final Selection (Week 4)

- Create comparison spreadsheet scoring each manufacturer on:

- Product quality (30 points)

- Business reliability (25 points)

- Value proposition (20 points)

- Technical support (15 points)

- Warranty coverage (10 points)

- Arrange factory visit for top 1-2 candidates if feasible

- Negotiate final terms including payment schedule, delivery timeline, and warranty details

- Request draft contract for legal review before commitment

Documentation Checklist Before Purchase: □ Complete product specifications with material composition □ Certification copies with verification □ Warranty document with clear terms □ Installation guide and technical support contact □ Payment and delivery terms in writing □ Client references contacted and verified □ Sample boards matching final order specifications □ Return/replacement policy for damaged or defective goods

Conclusion: Your Path to WPC Success

Selecting a reliable WPC manufacturer requires diligence, but the investment in proper evaluation pays exponential dividends. The difference between a hastily chosen supplier and a carefully vetted partner often means 15+ additional years of product performance and thousands of dollars in avoided replacement costs.

Focus your evaluation on these five critical factors: manufacturing technology and capabilities, product quality verification through testing and certifications, transparent business practices with verifiable track records, comprehensive warranty coverage with clear claim processes, and genuine technical support extending beyond the sale.

Don’t let attractive pricing override quality indicators. Remember: the cheapest WPC manufacturer rarely delivers the best value, and the most expensive doesn’t automatically guarantee superiority. Seek the optimal balance of proven quality, fair pricing, and reliable support.

Your Next Steps:

- Download this evaluation framework and create your comparison spreadsheet

- Request samples from 3-5 manufacturers using the questions provided throughout this guide

- Schedule detailed consultations with shortlisted suppliers

- Conduct reference checks with their past clients

- Make your decision based on total value, not just initial cost

The perfect WPC manufacturer for your project combines technical excellence, business stability, transparent communication, and unwavering commitment to customer success. By following this comprehensive framework, you’ll confidently identify that ideal partner and ensure your wood plastic composite investment delivers beauty, performance, and durability for decades to come.

Ready to start your evaluation? Begin by requesting samples and asking the specific questions outlined in each section—your future self will thank you for the thorough approach.