Table of Contents

When it comes to international construction supply, quality isn’t just a checkbox—it’s the foundation of successful projects and lasting business relationships. A china one stop construction material shop serves as a comprehensive partner for procurement managers, contractors, and importers seeking reliable building materials. But how do these suppliers ensure that materials shipped across continents meet rigorous quality standards?

The global construction materials market reached $1.17 trillion in 2023, with China accounting for approximately 28% of worldwide production. This dominant position comes with significant responsibility. Quality failures in construction materials can lead to project delays, cost overruns, safety hazards, and reputational damage. That’s why understanding quality assurance mechanisms is crucial for anyone sourcing from a construction materials supplier China.

This comprehensive guide examines the multi-layered approach that reputable Chinese construction material shops employ to guarantee quality. From factory-level inspections to third-party certifications, you’ll discover the specific processes, standards, and technologies that protect your investment and ensure project success.

What Is a China One Stop Construction Material Shop?

A china one stop construction material shop operates as a centralized sourcing platform that connects international buyers with a diverse range of building materials from multiple manufacturers. Rather than managing relationships with dozens of individual factories, buyers work with a single point of contact that handles everything from product selection to quality verification and logistics coordination.

Core Services Offered

These platforms typically provide comprehensive services including product sourcing across categories like steel, cement, tiles, hardware, insulation, and finishing materials. They coordinate factory audits, arrange pre-shipment inspections, manage export documentation, and consolidate shipments to reduce costs. The one-stop sourcing solution model streamlines procurement while maintaining quality oversight across all product lines.

Why the Model Matters for Quality

The aggregated purchasing power of a China building materials manufacturer network allows these shops to enforce stricter quality standards than individual buyers could negotiate. They leverage long-term relationships with certified factories, maintain dedicated quality control teams, and invest in testing infrastructure that wouldn’t be economically viable for smaller operations.

The Importance of Quality in Construction Materials

Quality in construction materials directly impacts structural integrity, project timelines, budget control, and long-term performance. According to McKinsey research, quality-related issues account for 30-40% of construction project delays globally. When materials fail to meet specifications, the cascading effects can be devastating.

Financial Impact of Quality Failures

The Construction Industry Institute found that rework costs average 12.4% of total project costs, with material defects being a primary contributor. When sourcing bulk construction materials China, a single container of substandard products can cost $50,000-$150,000 in replacement materials, shipping, storage, and labor—not counting project delays and potential legal liability.

Safety and Regulatory Compliance

Beyond finances, quality failures create safety risks. Substandard structural steel, defective electrical components, or contaminated insulation can lead to building failures, fires, or health hazards. Regulatory bodies worldwide have tightened import requirements, making certified building materials not just preferable but mandatory for many applications.

💡 PRO TIP:

Always request material test reports (MTRs) before finalizing orders. Reputable suppliers should provide documentation showing results from third-party testing labs without hesitation. If a supplier resists or delays providing MTRs, consider it a red flag.

Brand Reputation and Long-Term Relationships

For contractors and importers, reputation is everything. Using quality materials from a reliable building materials wholesale partner enhances professional standing and leads to repeat business. Conversely, quality failures damage client relationships and can result in litigation that threatens business viability.

Quality Control Processes in Chinese Construction Material Shops

Effective quality control construction materials systems employ multiple verification stages from raw material procurement through final shipment. Leading Chinese suppliers have developed sophisticated quality management frameworks that rival international competitors.

Factory Qualification and Auditing

Before any factory joins the approved supplier network, a china one stop construction material shop conducts comprehensive facility audits. These evaluations examine production capabilities, quality systems, equipment calibration, worker training, and environmental controls. Only manufacturers demonstrating consistent quality earn approval status.

Audits typically follow ISO 19011 guidelines and assess documentation systems, process controls, testing procedures, and corrective action protocols. Annual re-audits ensure ongoing compliance, with quarterly spot checks for high-volume suppliers.

In-Process Quality Monitoring

Quality control doesn’t wait until production completes. Modern construction material quality assurance programs include during-production inspections (DUPRO) that verify conformance at critical manufacturing stages. For example, steel reinforcement inspections occur after cutting but before bending, while ceramic tile quality checks happen after glazing but before firing.

Statistical process control (SPC) charts track key parameters in real-time, triggering alerts when measurements drift outside acceptable ranges. This proactive approach prevents defects rather than detecting them after completion.

Pre-Shipment Inspection Protocols

Before any international construction supply leaves China, comprehensive final inspections verify that finished products meet specifications. Inspectors typically examine samples representing 10-15% of the shipment using AQL (Acceptable Quality Limit) sampling standards. The inspection covers dimensions, appearance, functionality, packaging, and labeling.

Detailed inspection reports include photographic evidence, measurement data, and pass/fail determinations for each quality criterion. Buyers receive these reports before shipment authorization, providing an opportunity to address issues before materials leave the factory.

Laboratory Testing and Certification

Independent construction material testing laboratories accredited to ISO/IEC 17025 conduct specialized analyses that verify material properties. These tests include tensile strength for steel, compressive strength for concrete products, thermal conductivity for insulation, and chemical composition for various materials.

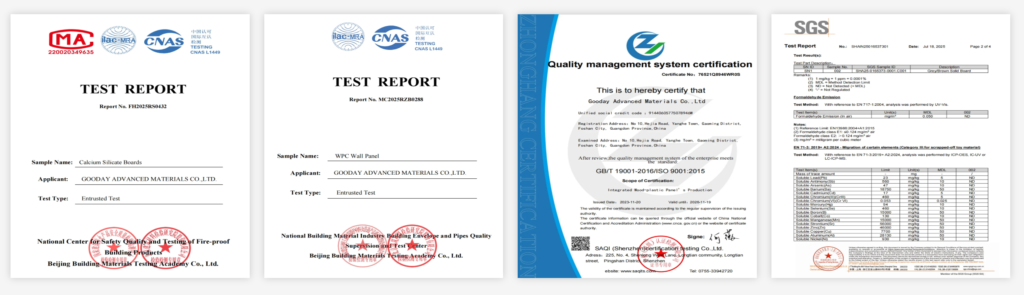

Third-party labs like SGS, Intertek, TÜV, and Bureau Veritas maintain facilities throughout China, providing unbiased verification. Testing frequency depends on material type and risk level, ranging from every batch for critical structural components to quarterly for stable commodity products.

Certifications and Standards That Ensure Quality

International certifications provide standardized benchmarks that transcend language barriers and geographical boundaries. When evaluating a china one stop construction material shop, understanding the certification landscape helps buyers make informed decisions.

ISO 9001 Quality Management Systems

ISO 9001 certification demonstrates that a manufacturer maintains documented quality management systems covering all aspects of production. The standard requires process documentation, customer focus, leadership commitment, risk-based thinking, and continuous improvement. Over 75% of reputable Chinese construction material manufacturers hold valid ISO 9001 certificates.

However, buyers should verify certification authenticity through the issuing body’s database. Fraudulent certificates exist, so independent verification protects against counterfeit documentation.

CE Marking for European Markets

CE marking indicates conformity with European health, safety, and environmental protection standards. For certified building materials destined for EU markets, CE compliance is mandatory. The marking process requires technical documentation, conformity assessment procedures, and often involves notified body verification.

Products covered under Construction Products Regulation (CPR) must undergo third-party testing and factory production control assessment by EU-notified bodies before receiving CE certification.

ASTM International Standards

American Society for Testing and Materials (ASTM) standards govern material specifications, testing methods, and performance requirements for North American markets. ASTM standards are voluntary but widely referenced in specifications and contracts. Common standards include ASTM A615 for steel reinforcement, ASTM C150 for Portland cement, and ASTM E84 for flame spread testing.

Reputable suppliers maintain up-to-date knowledge of applicable ASTM standards and can provide test reports demonstrating compliance. When sourcing building materials wholesale for US projects, ASTM compliance verification is essential.

GB Standards (Chinese National Standards)

GB (Guobiao) standards represent Chinese national standards that manufacturers must meet for domestic sales. Many GB standards align with international equivalents, though some specifications differ. Understanding GB standards helps buyers assess whether Chinese products meet baseline quality thresholds.

Key GB standards include GB/T 1499 for steel bars, GB 175 for cement, and GB/T 11981 for building materials radioactivity. Compliance with GB standards doesn’t automatically ensure international standard compliance, so buyers should verify alignment with their target market requirements.

Environmental and Safety Certifications

Modern construction material quality assurance extends beyond mechanical properties to environmental impact. Certifications like RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization of Chemicals), and Green Guard verify low emissions and chemical safety.

LEED (Leadership in Energy and Environmental Design) projects increasingly require materials documentation proving sustainability credentials. Forward-thinking Chinese suppliers invest in environmental certifications to access premium market segments.

How to Verify Quality When Sourcing from China

Quality verification requires active engagement rather than passive acceptance of supplier claims. Buyers who implement systematic verification protocols substantially reduce quality risks when working with a construction materials supplier China.

Documentation Review Process

Start by requesting comprehensive documentation including business licenses, export certifications, quality management certificates, product test reports, and customer references. Verify certificate authenticity by contacting issuing organizations directly. Check that product specifications match your requirements exactly—subtle differences in dimensions, tolerances, or materials can create significant problems.

Review material safety data sheets (MSDS) for any products containing chemicals, adhesives, or coatings. Ensure compliance with destination country regulations regarding VOC emissions, flame retardants, and restricted substances.

Physical Sample Testing

Never commit to large orders without testing physical samples. Request production samples—not golden samples created specifically for sales purposes. Have samples tested by independent laboratories in your country to verify conformance with local standards. Destructive testing may be necessary for structural materials like steel or concrete products.

Compare sample performance against competing products and established benchmarks. Document all test results for future reference and to establish baseline expectations for production orders.

Factory Visits and Audits

When feasible, conduct in-person factory visits before finalizing supplier relationships. Observe production processes, inspect quality control procedures, review testing equipment, and meet the management team. Factory conditions reveal important information that documentation cannot capture.

Look for organized workspaces, calibrated testing equipment, documented procedures, trained personnel, and evidence of ongoing quality management. Warning signs include disorganized facilities, missing documentation, outdated equipment, or resistance to questions about quality systems.

💡 PRO TIP:

Schedule factory visits during actual production runs, not just tours. Arrive unannounced if possible, or at least don’t provide extensive advance notice. This prevents ‘show floor’ preparations that may not reflect daily operations. During visits, speak directly with production workers—they often provide honest insights about quality practices.

Third-Party Inspection Services

Engage independent inspection companies to conduct pre-shipment verifications. These organizations employ trained inspectors who assess products against your specifications using standardized protocols. Inspection services typically cost $200-$500 per visit—a small investment compared to potential defect costs.

Specify exactly what inspectors should verify: dimensions, materials, functionality, packaging, labeling, and quantity. Provide detailed acceptance criteria so inspectors can make objective pass/fail determinations. Request photographic documentation and detailed reports within 24-48 hours of inspection.

Establishing Quality Agreements

Formalize quality expectations through written agreements that specify standards, testing requirements, acceptance criteria, and remediation procedures. Quality agreements should address sampling methods, defect definitions, acceptable quality limits, and consequences for non-conformance.

Include provisions for corrective actions, replacement timelines, and financial remedies. Clear agreements prevent misunderstandings and provide legal recourse if quality issues arise.

Benefits of Choosing a One-Stop Construction Material Shop in China

The one-stop sourcing solution model offers substantial advantages beyond simple convenience. These benefits directly impact quality outcomes, cost efficiency, and operational effectiveness.

Centralized Quality Management

Working with a single china one stop construction material shop means dealing with one quality system instead of managing multiple factory relationships. The shop maintains consistent inspection protocols, documentation standards, and testing procedures across all product categories. This uniformity simplifies verification and reduces coordination complexity.

Economies of Scale in Testing

Large-volume purchasers can justify more extensive testing programs. A building materials wholesale operation conducts thousands of tests annually, spreading fixed costs across numerous transactions. This makes comprehensive construction material testing economically viable where individual buyers might skimp on verification to control costs.

Leverage and Accountability

Aggregated purchasing power gives one-stop shops significant leverage with manufacturers. Factories depend on high-volume orders and cannot afford to deliver substandard products. This relationship dynamic creates stronger accountability than individual buyers typically achieve. When quality issues arise, resolution happens faster because factories prioritize their largest customers.

Supply Chain Efficiency

Consolidating orders from multiple factories into single shipments reduces logistics costs and complexity. Container optimization improves freight economics while reducing environmental impact. One-stop shops coordinate production schedules across suppliers, ensuring simultaneous completion that enables complete project material deliveries rather than piecemeal shipments.

Market Intelligence and Product Development

Established shops maintain deep market knowledge spanning multiple product categories. They understand emerging trends, new technologies, and changing regulations. This intelligence helps buyers make informed decisions about material selection, specification updates, and alternative products that may offer superior performance or value.

Quality Verification Methods Comparison

| Method | Cost | Reliability | Best For |

| Supplier Self-Certification | Lowest ($0) | Low-Medium | Established relationships, low-risk items |

| Physical Sample Testing | $500-$2,000 | High | New suppliers, critical materials |

| Factory Audits | $3,000-$8,000 | Very High | High-volume contracts, long-term relationships |

| Third-Party Inspection | $200-$500 | High | All orders, ongoing quality monitoring |

| Laboratory Testing | $300-$3,000 | Very High | Structural materials, regulatory compliance |

Common Quality Challenges and How They Are Addressed

Understanding common quality challenges helps buyers anticipate problems and evaluate how effectively a china one stop construction material shop addresses risk factors inherent in international construction supply.

Specification Misunderstandings

Cultural and language differences sometimes create specification ambiguities. Metric versus imperial units, terminology variations, and standard interpretations can lead to products that technically meet stated specifications but fail functional requirements. Reputable suppliers address this through detailed technical reviews, 3D models or technical drawings confirmation, and pre-production samples that verify mutual understanding before full production begins.

Material Substitution Risks

Cost pressures may tempt some manufacturers to substitute specified materials with cheaper alternatives. Steel grades, cement types, insulation materials, and component qualities can vary substantially while appearing superficially similar. Quality-focused bulk construction materials China suppliers combat this through rigorous incoming material verification, laboratory testing of raw materials, and supplier qualification programs that vet material sources.

Production Consistency Issues

Maintaining consistent quality across large production runs challenges any manufacturer. Process variables, operator changes, equipment wear, and material batch variations introduce quality drift. Advanced suppliers implement statistical process control, automated monitoring systems, and regular calibration schedules. They also conduct in-process inspections at multiple production stages rather than relying solely on final inspection.

Packaging and Handling Damage

Quality products arriving damaged due to inadequate packaging or rough handling negate manufacturing excellence. Professional suppliers design packaging specifically for ocean freight stresses, using appropriate cushioning, moisture barriers, and structural reinforcement. They also conduct drop tests and environmental conditioning to validate packaging before use.

💡 PRO TIP:

Implement a “golden sample” program where you retain approved samples from the first acceptable production run. All future shipments should match this golden sample. Store samples in controlled conditions and reference them during inspections. This creates an objective quality standard that prevents gradual specification drift over time.

Regulatory Compliance Gaps

Standards and regulations evolve continuously. Products compliant last year may violate current requirements. Leading suppliers maintain regulatory intelligence systems tracking changes in key markets. They proactively update products and testing protocols, ensuring ongoing compliance. They also maintain relationships with certification bodies and testing laboratories that provide early warning of regulatory changes.

Technology and Innovation in Quality Assurance

Modern construction material quality assurance increasingly leverages advanced technologies that enhance accuracy, efficiency, and transparency. Progressive Chinese suppliers invest in these innovations to differentiate themselves and meet demanding international buyer expectations.

Automated Optical Inspection Systems

Computer vision systems equipped with high-resolution cameras and AI algorithms can detect surface defects, dimensional variations, and color inconsistencies at speeds impossible for human inspectors. These systems inspect 100% of production rather than statistical samples, identifying problems before defective products reach customers. For products like tiles, facades, and finished hardware, automated inspection provides unprecedented quality consistency.

X-Ray and Ultrasonic Testing

Non-destructive testing technologies allow internal structure examination without damaging products. X-ray inspection reveals internal voids, inclusions, or structural irregularities in castings, welds, and composite materials. Ultrasonic testing detects cracks, delamination, and density variations. These technologies provide quality insights that surface inspection cannot match, particularly for structural certified building materials.

Blockchain Traceability Systems

Blockchain technology creates immutable records tracking materials from raw material sources through manufacturing and shipping. Each quality checkpoint—material receipt, production stage completion, testing, and inspection—generates timestamped, verifiable records. Buyers can access complete quality documentation knowing records cannot be altered retroactively. This transparency builds confidence in quality claims.

IoT Sensors and Real-Time Monitoring

Internet of Things sensors embedded in production equipment monitor critical parameters continuously. Temperature, pressure, humidity, dimension, and speed sensors feed data to centralized systems that detect anomalies immediately. This real-time monitoring enables instant corrective action rather than discovering problems after production completion. Buyers can even access live production data, creating unprecedented transparency.

AI-Powered Predictive Quality Analytics

Machine learning algorithms analyze historical quality data to identify patterns predicting future quality issues. These systems might detect that certain raw material batches, equipment settings, or environmental conditions correlate with defect rates. Proactive adjustments prevent quality problems before they occur. For building materials wholesale operations managing multiple product lines, predictive analytics optimize quality across the entire portfolio.

Digital Twin Simulations

Digital twin technology creates virtual replicas of production processes. Suppliers can simulate process changes, test new materials, or evaluate quality impact of modified procedures—all without disrupting actual production. This capability accelerates continuous improvement while minimizing risk. Buyers benefit from suppliers who can rapidly adapt to new requirements while maintaining quality consistency.

Case Studies: Quality Success Stories

Real-world examples demonstrate how effective quality management through a china one stop construction material shop delivers measurable results. These case studies illustrate quality assurance principles in action.

Case Study 1: Middle East Infrastructure Project

A major contractor needed bulk construction materials China for a $2.3 billion transportation project in Dubai. The challenge involved coordinating supply of structural steel, reinforcement bars, fasteners, and concrete additives—all requiring compliance with strict UAE and international standards.

The selected one-stop shop implemented comprehensive quality protocols including third-party testing for all structural materials, pre-shipment inspections documented with photographs and video, and real-time tracking of test results through a web portal. During the 18-month supply period, they delivered 47 containers with zero material rejections—a rejection rate 93% below the contractor’s typical international sourcing experience. Project completion occurred two weeks ahead of schedule partially due to reliable material supply.

Case Study 2: European Green Building Initiative

A European developer pursuing LEED Platinum certification needed environmentally compliant materials for a 200-unit residential complex. They required documentation proving low VOC emissions, sustainable sourcing, and recyclability—requirements often challenging with construction materials supplier China partners.

The chosen supplier specialized in green building products and maintained relationships with certified sustainable manufacturers. They provided comprehensive documentation including third-party environmental test reports, factory sustainability audits, and material health certificates. All supplied products met or exceeded LEED requirements. The project achieved Platinum certification, with the developer crediting thorough material documentation as instrumental to certification success.

Case Study 3: North American Retail Chain Expansion

A retail chain planned 35 new stores across the United States within 12 months. They needed standardized certified building materials including flooring, lighting fixtures, HVAC components, and storefront systems—all meeting US building codes and matching corporate design standards exactly.

The one-stop shop created a master specification for all 35 locations, established golden samples for quality comparison, and implemented project-specific quality control protocols. They coordinated production schedules ensuring sequential delivery aligned with construction timelines. All materials arrived on schedule with quality matching approved samples. The retail chain saved an estimated $1.8 million compared to domestic sourcing while achieving identical quality standards.

How to Choose the Right China One Stop Construction Material Shop

Selecting the right one-stop sourcing solution partner requires careful evaluation beyond price considerations. Quality-conscious buyers should assess multiple factors that indicate quality management capability and reliability.

Quality System Credentials

Verify that candidates hold relevant quality certifications including ISO 9001 for quality management systems and product-specific certifications appropriate to your needs. Request evidence of third-party laboratory relationships and inspection service partnerships. Examine whether they employ dedicated quality professionals with relevant qualifications and experience.

Track Record and References

Request references from customers in your geographic region or industry. Contact references directly and ask specific questions about quality performance, defect rates, responsiveness to quality issues, and documentation quality. Years in business, repeat customer rates, and customer diversity provide useful indicators of reliability.

Transparency and Communication

Evaluate communication responsiveness, technical knowledge, and willingness to provide detailed information. Quality suppliers welcome detailed questions about their processes and readily share documentation. Reluctance to discuss quality systems or provide specifics suggests potential problems.

Product Range and Specialization

Assess whether the supplier’s product portfolio aligns with your needs. Specialist suppliers focusing on specific material categories may offer deeper expertise than those attempting to source everything. Conversely, true one-stop solutions should demonstrate competence across multiple categories rather than superficial coverage.

Quality Supplier Evaluation Checklist

Essential Documentation:

- Valid business license and export certifications

- ISO 9001 or equivalent quality management certification

- Product-specific certifications (CE, ASTM, etc.)

- Third-party laboratory partnerships documentation

- Sample quality agreements and contracts

Quality Process Requirements:

- Documented factory qualification procedures

- In-process quality monitoring protocols

- Pre-shipment inspection offerings

- Material testing and certification procedures

- Quality issue resolution protocols

Communication and Support:

- Responsive communication (within 24 hours)

- English proficiency of technical staff

- Dedicated account management

- Transparent pricing and terms

- Willingness to arrange factory visits

Value-Added Services:

- Product sourcing assistance

- Logistics coordination and consolidation

- Customs documentation support

- Market intelligence and product recommendations

- Post-delivery support and warranty administration

Trial Order Strategy

Before committing to large contracts, place smaller trial orders that test the supplier’s quality management. Evaluate documentation quality, inspection thoroughness, communication responsiveness, and actual product quality. Trial orders reveal operational reality better than sales presentations.

Conclusion: Quality as the Foundation of Successful Sourcing

Quality assurance in international construction supply requires systematic approaches that span from manufacturer qualification through final delivery. A reputable china one stop construction material shop distinguishes itself through comprehensive quality management systems that protect buyers from the risks inherent in cross-border sourcing.

The multi-layered quality assurance framework—combining factory audits, in-process monitoring, laboratory testing, certifications, and pre-shipment inspections—creates redundant safeguards that catch potential issues at multiple checkpoints. Technology innovations including AI inspection, blockchain traceability, and IoT monitoring are elevating quality standards beyond what manual processes could achieve.

For procurement managers, contractors, and importers, understanding how quality control construction materials systems function enables informed supplier selection and effective quality management. The investment in proper verification—whether through sample testing, third-party inspections, or factory audits—pays returns many times over by preventing costly quality failures.

As global construction markets evolve, quality expectations continue rising. Suppliers who invest in robust quality systems, transparent processes, and continuous improvement position themselves as valuable long-term partners. Buyers who prioritize quality verification alongside cost considerations build supply chains that support project success and business growth.

Ready to Source with Confidence?

Partner with a china one stop construction material shop that demonstrates commitment to quality through documented processes, international certifications, and proven track records. Request detailed information about quality management systems, arrange factory visits, and start with trial orders to verify quality capabilities firsthand. The right partner transforms international sourcing from a risky challenge into a competitive advantage.

Frequently Asked Questions About Quality Assurance in Chinese Construction Material Shops

Q1: How can I verify that quality certifications from Chinese suppliers are authentic?

Verify certification authenticity by visiting the issuing organization’s website and using their certification lookup database. Most reputable certification bodies (ISO, SGS, TÜV, etc.) maintain online verification systems where you can enter certificate numbers to confirm validity. Additionally, request original certificates rather than copies, check expiration dates, and verify that the certified entity name exactly matches your supplier’s legal business name. For critical purchases, consider hiring third-party verification services that specialize in credential authentication.

Q2: What is the typical cost of third-party quality inspection services in China?

Third-party inspection services typically cost $200-$500 per inspection visit, depending on product complexity, inspection duration, location, and specific requirements. Laboratory testing adds $300-$3,000 depending on test types—basic dimensional checks cost less than comprehensive material analysis or destructive testing. Factory audits range from $3,000-$8,000 for comprehensive assessments. While these costs may seem significant, they represent 0.1-2% of typical order values and prevent quality failures that could cost 10-50 times more.

Q3: How do Chinese GB standards compare to international standards like ASTM or EN?

Chinese GB standards often align with international standards but may include different test methods, tolerance ranges, or performance criteria. Many GB standards were developed referencing international equivalents, creating substantial overlap. However, direct substitution isn’t always safe—some GB standards are more stringent while others are less demanding than international counterparts. Always review actual standard requirements rather than assuming equivalence. Reputable suppliers understand these nuances and can demonstrate how their products meet both GB and international standards when necessary.

Q4: What should I do if I discover quality issues after materials arrive?

Document quality issues immediately with photographs, measurements, and detailed descriptions. Notify your supplier within timeframes specified in your contract (typically 7-14 days after delivery). Engage third-party inspectors to provide independent verification of defects—this creates objective documentation supporting claims. Stop using defective materials to prevent compounding problems. Review your quality agreement to understand remedy options: replacement, partial refund, or full refund. Consider involving inspection companies or quality consultants who can mediate between parties and provide technical assessment. Most reputable suppliers respond constructively to legitimate quality complaints, especially when supported by objective documentation.

Q5: Is it necessary to visit factories in person, or are remote quality verification methods sufficient?

Factory visits provide valuable insights that remote verification cannot fully replicate, but they’re not always necessary. For high-value orders, long-term partnerships, or critical applications, in-person visits are highly recommended. They allow you to observe production conditions, meet management teams, inspect quality systems firsthand, and assess factory capabilities comprehensively. However, for smaller orders or when working through trusted intermediaries, remote verification combining document review, sample testing, third-party inspections, and video factory tours often suffices. Many buyers use a hybrid approach: remote verification for initial orders and factory visits before committing to substantial long-term contracts.

Q6: How can I ensure consistent quality across multiple shipments from the same supplier?

Maintain consistency through several strategies: establish golden samples from the first acceptable shipment and require all future shipments to match; implement pre-shipment inspections for every order, not just initial purchases; specify Acceptable Quality Limits (AQL) in contracts with clearly defined acceptance criteria; request batch test reports showing production dates and quality test results; schedule periodic factory audits to verify continued process compliance; track quality metrics over time and address negative trends proactively. Additionally, maintain open communication channels and provide feedback—both positive and negative—so suppliers understand your expectations clearly.